Cloud-based ERP for manufacturing — made easy

QT9™ ERP enables you to centralize business processes on one platform that scales with your needs.

Browse by industry

QT9 ERP, a cloud-based ERP for manufacturing, automates Device History Records and

Electronic Batch Records for life sciences, medical

device manufacturers, pharma and biotech companies.

Integrate data across business processes

Integrate all departments and functions into a single, global ERP software.

360-Degree View

Unify Multiple Sites

Stay Organized

Boost productivity

Discover how easy QT9 ERP, a cloud based ERP for manufacturing, makes it to increase productivity, profitability and efficiency by eliminating time-consuming, error-prone manual processes.

-

Automate inventory control with barcoding through our advanced manufacturing ERP system.

-

Optimize production with automatic job scheduling and capacity planning- fully integrated into your ERP solution for manufacturing.

-

Streamline processes from ERP to QMS for fast resolution.

-

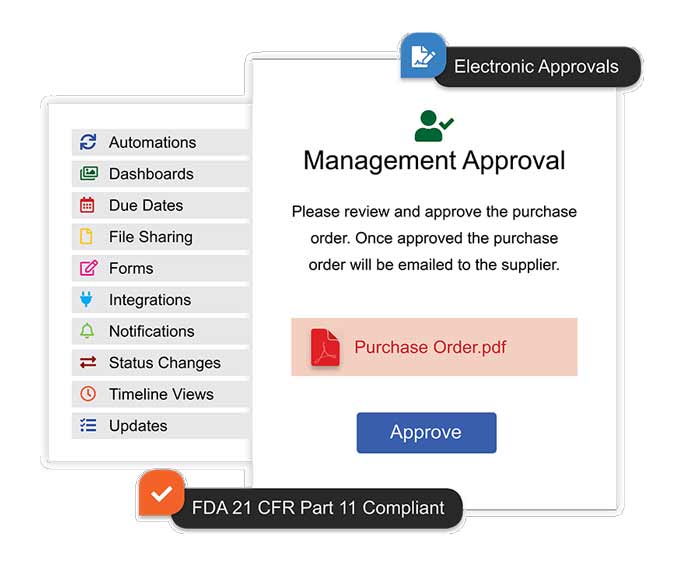

Electronically approve MBR, DMR, eBR, and DHRs with regulatory-compliant signatures.

-

Manage the supply chain and accelerate product delivery by synchronizing purchase orders, receipts, invoices and returns- all within one scalable ERP for maanufacturing solution.

Drive innovation with cloud ERP for manufacturing

Accelerate innovation with the next-generation mobile capabilities and global administrative tools on QT9 ERP's easy-to-use, scalable and secure cloud-baed ERP for manufacturing platform.

-

Go paperless by using our intuitive manufacturing ERP shop floor manager.

-

Adapt quickly with QT9 ERP's scalable platform.

-

Dynamically populate forms with data inherited from other modules and receive status updates- streamlining processes across your ERP for manufacturing workflows.

-

Improve quality by integrating QT9 ERP directly with the QT9 Quality Management System (QMS), while ensuring ISO and FDA compliance- making it the best ERP for manufacturing environments focused on innovation and regulatory standards.

Redefine value

QT9 ERP's highly adaptive cloud-based ERP for manufacturing platform includes a comprehensive and evolving feature list combined with a user-friendly experience that enables future growth.

-

Every module is included- perfect for those seeking complete ERP solution for manufacturing. No hidden costs.

-

QT9 ERP is quick to implement, so you can improve your ROI faster.

- Customer, Compliance, Supplier and Physical Inventory Web portals are included in our scalable manufacturing ERP system.

-

No expensive/on-going customizations or slow implementations.

.png)

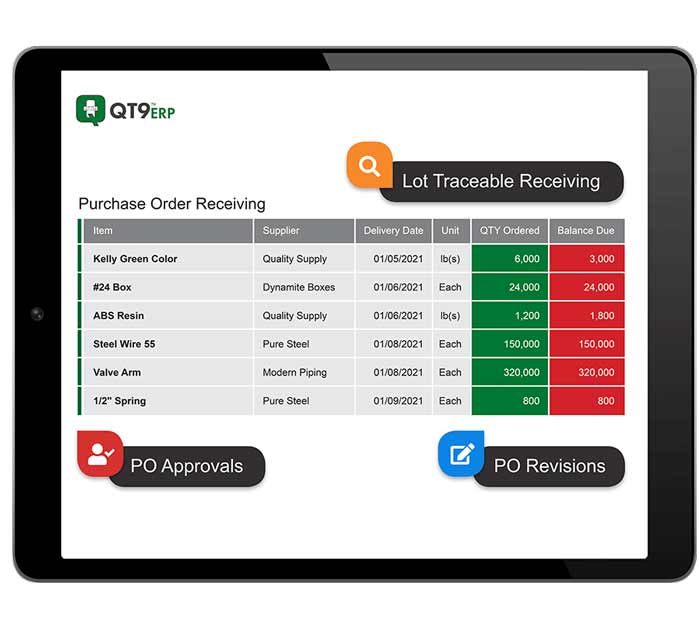

Improve traceability

Experience total traceability with QT9 ERP, a leading cloud- based ERP for manufacturing. Track every move from purchasing to manufacturing, to the warehouse and to the sales order.

-

Track by lot number or serial number including accurate unit cost- essential features in a manufacturing ERP.

-

Enable multi-location inventory tracking to track inventory across locations anywhere.

-

Transactional timelines provide you with a complete audit trail to support compliance and visibility across your cloud ERP manufacturing workflows.

- Manage expiration dates to help ensure the quality of your inventory.

Unlock insights

QT9 ERP, a cloud based ERP for manufacturing gives you access to digital business intelligence and analytics essential for any size organization. Get greater visibility into your business performance to make informed strategic decisions.

-

Turn data-driven insights into opportunities with real-time interactive dashboards.

-

Plan purchasing needs and minimize costs with better planning and purchasing forecasts.

-

Respond quickly against recalls and returns with full traceability.

QT9 ERP seamlessly integrates with QT9's quality management software suite

Automatically sync your suppliers, customers, and products across QT9 ERP and QT9 QMS and experience a unified system for managing quality and business operations.

Non-Conformance & CAPA Management

Non-conformance and CAPA management

Nonconforming product records and corrective actions can be created in QT9 QMS right from event-driven actions in QT9 ERP. These include PO receiving, inspection and history, as well as from the Jobs/Manufacturing and customer sales and service areas. By giving users the ability to create non-conformance and CAPA records from the ERP, there is full data transfer and permanent linking to your QMS records in the ERP, saving time and maintaining historical data about quality actions in your ERP.

Supplier & Vendor Management

Supplier and vendor management

QT9 ERP maintains supplier records, while QT9 QMS tracks supplier quality performance and audits. Supplier-related nonconformances, engineering changes, audits and other quality processes in QT9 QMS sync with vendor records in QT9 ERP to ensure compliance.

Document Control & Revision Management

Document control and revision management

QT9 QMS document control links with QT9 ERP to ensure only approved, up-to-date documents (e.g., SOPs, work instructions) are accessible for production, engineering and quality teams.

QT9 QMS documents can be approved as part of QT9 ERP Bill of Materials and enable seamless passthrough to the Shop Floor Manager. This gives production-floor employees access to the latest approved work instructions and other controlled documents.

Production & Purchasing Inspections

Production and purchasing inspections

Work orders and production processes in QT9 ERP can create quality inspections in QT9 QMS, transferring the proper manufacturing data to the inspection record.

PO receiving can generate the proper QT9 QMS inspection record for your supplier and material-specific inspections.

Customer Complaints & Returns (RMA Process)

Customer complaints and returns (RMA process)

Customer returns in QT9 ERP have the ability to generate customer complaints and feedback records in QT9 QMS, creating a seamless customer service and quality experience.

Root cause analysis in QT9 QMS feeds into ERP adjustments for inventory, production and supplier performance.

Non-conformance and CAPA management

Nonconforming product records and corrective actions can be created in QT9 QMS right from event-driven actions in QT9 ERP. These include PO receiving, inspection and history, as well as from the Jobs/Manufacturing and customer sales and service areas. By giving users the ability to create non-conformance and CAPA records from the ERP, there is full data transfer and permanent linking to your QMS records in the ERP, saving time and maintaining historical data about quality actions in your ERP.

Supplier and vendor management

QT9 ERP maintains supplier records, while QT9 QMS tracks supplier quality performance and audits. Supplier-related nonconformances, engineering changes, audits and other quality processes in QT9 QMS sync with vendor records in QT9 ERP to ensure compliance.

Document control and revision management

QT9 QMS document control links with QT9 ERP to ensure only approved, up-to-date documents (e.g., SOPs, work instructions) are accessible for production, engineering and quality teams.

QT9 QMS documents can be approved as part of QT9 ERP Bill of Materials and enable seamless passthrough to the Shop Floor Manager. This gives production-floor employees access to the latest approved work instructions and other controlled documents.

Production and purchasing inspections

Work orders and production processes in QT9 ERP can create quality inspections in QT9 QMS, transferring the proper manufacturing data to the inspection record.

PO receiving can generate the proper QT9 QMS inspection record for your supplier and material-specific inspections.

Customer complaints and returns (RMA process)

Customer returns in QT9 ERP have the ability to generate customer complaints and feedback records in QT9 QMS, creating a seamless customer service and quality experience.

Root cause analysis in QT9 QMS feeds into ERP adjustments for inventory, production and supplier performance.

QT9 ERP software key features

Companies, both big and small, are growing their business with QT9 ERP.

Manufacturing

QT9 ERP helps busy manufacturers meet customer demands and quickly adapt to market changes.

-

Generate Bill of Materials (BOM) quickly and accurately.

-

Automate your shop floor and go paperless with barcoding.

-

Quickly analyze manufacturing efficiencies with real-time data.

-

Ensure product consistency, quality and delivery.

-

Optimize labor, machines and inventory for ultimate efficiency.

Financial Management

QT9 ERP gives your team the tools to easily automate your financial functions and transactions.

-

Reduce redundant data entry by automating financial transactions.

-

Verify that every deposit, payment, withdrawal and transfer is correct.

-

Automate accounts receivable and accounts payable with ERP data.

-

View real-time financials and filter the data you want to see.

-

Synchronize financial systems across multiple locations.

Inventory Management

QT9 ERP makes it easy to keep enough inventory on hand in the right locations to meet demand.

-

Monitor inventory levels in real time across multiple locations.

-

Track items by containers, lot numbers, serial numbers and expiration dates.

-

Set up automatic reorder points based on sales and lead times.

-

Auto-allocate inventory and use notifications to prevent shortages.

-

Use barcodes to track usage, transfers and physical counts.

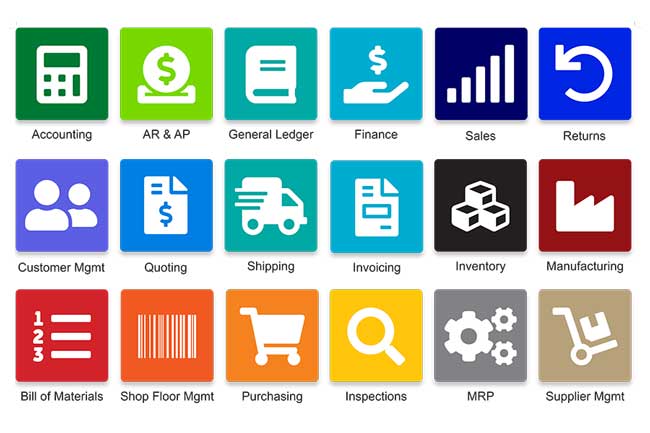

Pre-Installed Modules Included

Easily connect all your business functions with QT9's next-generation business modules.

“It’s a single solution to manage our ERP, MRP and QMS needs across all our business platforms.”

“Working in Class II medical devices it is important to use a validated system, QT9 checks this box at no additional cost.”

“All of the information that we need is easier to access with QT9 ERP, it makes having audits a breeze.”

Experience QT9 ERP in action today

Schedule your personalized demo and start a free trial.