Manufacturing ERP software- central command for manufacturing

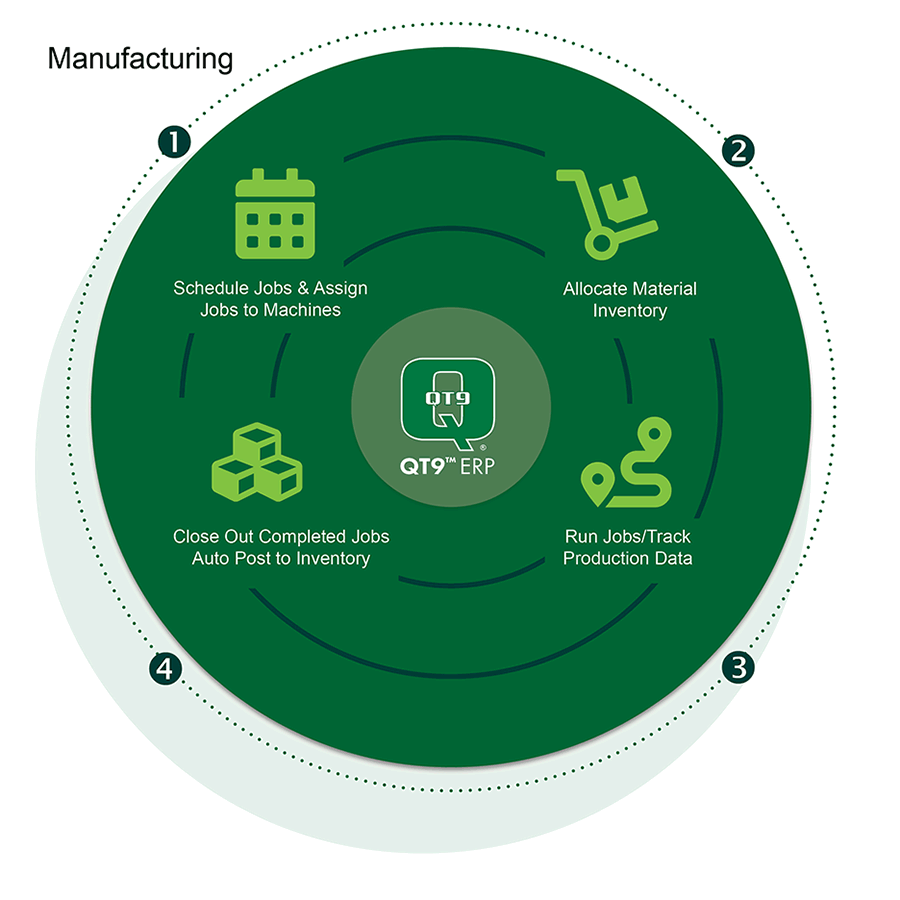

QT9 ERP is a powerful manufacturing ERP software that helps busy manufacturers meet customer demands and quickly adapt to market changes.

Connect manufacturing to the rest of your business

Enable purchasing, manufacturing, shipping and planning to work as one.

Optimized Scheduling

Schedule by using real-time production data, Gantt charts and forecasting.

Contract Services

Complete Traceability

Total Shop Floor Management

Simplify manufacturing

-

Eliminate spreadsheets that require manual data entry and constant updates.

-

Manage all your manufacturing operations in manufacturing ERP software.

-

Easily assign machines and set schedules.

-

Automatically allocate material inventory.

-

Quickly identify bottlenecks with multiple visual tools.

-

Gain complete visibility of the entire manufacturing demand.

-

Interact with material resource planning to ensure on-time job completion through reliabe manufacturing ERP software.

Modernize manufacturing

-

Automate manufacturing processes by automatically linking orders to jobs, shipping and invoicing.

-

Use our shop floor manager to go paperless, utilizing barcoding, file attachments and even tablets.

-

Link all jobs to the correct Bill of Material revision to ensure accuracy.

-

Forecast manufacturing needs based on sales, inventory and future potential.

-

Automatically create jobs from processed sales orders.

-

Create quality records in QT9 QMS for nonconforming products or corrective actions based on manufacturing information.

-

Ensure traceability by auto-generating serial numbers and lot numbers.

Monitor manufacturing

-

Get real-time insights with drill-down capabilities that allow you to view manufacturing processes the way you want.

-

Excel capabilities are included in every reporting interface.

-

Compare jobs to easily find inaccuracies or inefficiencies.

-

Visualize trends in our manufacturing reporting with grouping, filtering and comparative data in our robust dashboard grids.

-

Confront inefficiencies to eliminate repetitive tasks and manual entry from processing manufacturing through manufacturing ERP software.

-

Calculate percent yield on job materials at the click of a button.

-

Monitor manufacturing end-to-end by sales order, customer name, item name, part number, status, expected quantity, finished quantity, required date and lot number.

Manage all your manufacturing from one solution

Everything you need to get the job done.

FAQs

What is a manufacturing ERP system?

Standard ERP software is an operations management platform that automates and integrates front-end and back-end business processes, such as sales and order fulfillment. Manufacturing ERP software takes that model a few steps further, integrating activities that support effortless manufacturing operations, including:

- Bill of Materials (BOM)

- Inventory Control

- Supply Chain Management

- Quality Control

- Compliance

- Reporting and Analytics

How do manufacturing ERP systems work?

Manufacturing ERP applications unify production planning and resource management, so companies can better manage costs while optimizing inventory levels. Manufacturers use it to set production schedules and allocate material resources using bill of materials and machine utilization. More advanced ERP manufacturing systems can automatically link sales orders to jobs, automate job scheduling, link to MRP planning and get built-in traceability for reporting and analytics.

What are the benefits of using ERP software for manufacturers?

Manufacturing ERP software can deliver substantial benefits that go beyond simply automating tasks. These include:

- Integrated job scheduling / shop floor management

- Optimized physical and human resources

- Improved efficiency and productivity

- Real-time data, which affords better decision-making

- Improved customer satisfaction

- Simplified quality and compliance

What is the best ERP system for manufacturing?

In general, the best ERP software for manufacturing is a system that can address all your operational needs at the least cost. Manufacturers in particular should look for applications that include BOM, shop floor management and job scheduling. Other important features to look for include:

- Cloud-based architecture – these offer remote access and easier collaboration with other departments. Cloud-based systems also enable faster implementation, scalability and tend to be more user-friendly.

- Comprehensive vendor support, including training, implementation and ongoing assistance.

- Scalability – As your business grows, your ERP should be scalable enough to accommodate increased production volumes, new product lines or expanded facilities without requiring significant upgrades.

Why should I choose QT9 ERP as my total enterprise solution?

QT9 ERP is a comprehensive system that can work for any size company, in any industry. It improves efficiency and accuracy through integrated data and automated operations, all without breaking the bank.

QT9 ERP provides more than 17 modules as part of its standard offering, as well as easy access to data and analytics to help manufacturers make the best decisions for moving forward.

With QT9 ERP you get:

- Real-time, Centralized Inventory Control

- Barcoding and Scanning

- Warehouse Management

- Bill of Materials (BOM) Tracking

- Lot and Serial Traceability

- Manufacturing Operations Integration

- Job Scheduling

- Supply Chain Management

QT9 ERP seamlessly integrates with QT9’s highly rated quality management system (QMS) software. What’s more, you’ll get unlimited training, unlimited customer support, free software updates and tailored implementation support.

Experience QT9 ERP in action today

Schedule your personalized demo and start a free trial.