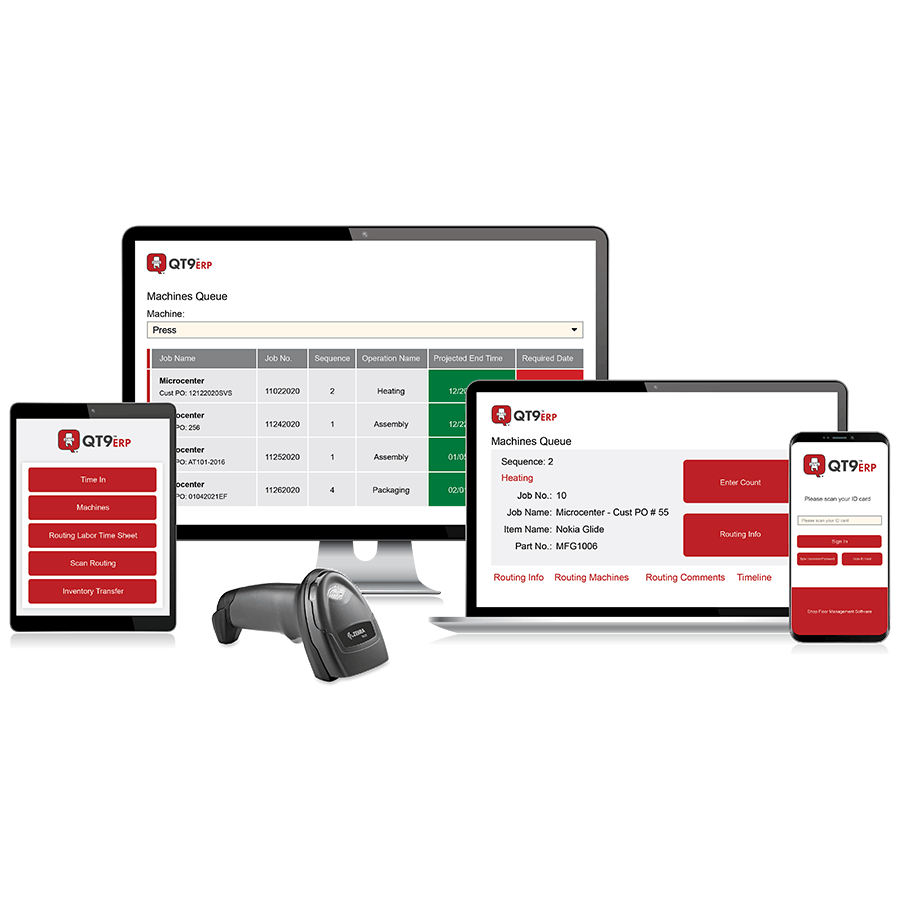

Drive productivity with smart shop floor management software

QT9™ ERP provides tools to manage your shop's workflow, including materials, build, job costing, time tracking and inventory.

Label inventory | Scan movement | Track status

QT9 ERP makes it easy to manage your shop floor.

Connect the shop floor to the rest of your business

Boost productivity

Become as paperless as possible on the shop floor, enabling employees to access job data in real time, including file attachments.

Complete traceability

Know who did what and when with a complete audit trail and transactional inventory.

Utilize barcodes

Integrate barcoding to track labor, accurately scan-in material inventory, perform inventory moves and even go paperless.

Simplify shop floor processes

-

Save time by enabling employees to quickly edit job data on the shop floor.

-

Easily track scrap for materials and manufactured items.

-

Track work orders across the shop floor from a kiosk or tablet.

- Simplify operations with Shop Floor Management Software that eliminates manual data entry and constant spreedsheet data.

-

Eliminate spreadsheets that require manual data entry and constant updates.

-

Enable employees to track machine counts to eliminate paper and pen.

-

Enable reconciling the allocated inventory to your jobs.

-

Ensure the correct parts and the correct inventory are used to promote job and inventory accuracy.

Modernize shop floor processes

-

Enable employees to easily time in and out on job routings, assign material inventory to jobs, complete routings, enter machine counts and track scrap.

-

Our Shop Floor Management Software provides Self-service platform enables employees to manage manufacturing, view job orders or update records.

-

Easily assign/move material inventory to routings and work areas via barcodes.

-

Go paperless utilizing barcoding, file attachments and even tablets.

-

Enforce inventory rules for material replacement or reconciliation.

-

Electronic signature compliant for quality control signoffs.

Streamline the shop floor

-

Print labels on demand for any running jobs on the shop floor.

-

View important file attachments, such as drawings, work instructions, etc., tied to the Bill of Materials.

-

Streamline job data by completing job routings in real time.

-

Track labor by timing in and timing out per routing using barcoding.

-

Compare projected job times to actual job times using real-time data entry to identify efficiencies and inefficiencies.

Manage all your manufacturing from one solution

Everything you need to get the job done.

FAQs

What is shop floor management?

Shop floor management involves organizing, monitoring and controlling all activities in a business’ production area. This includes coordinating workflows, assigning resources and tracking outcomes. The goal is to ensure production targets are met efficiently: reducing waste and increasing output while maintaining quality and keeping costs down.

Why is shop floor management important?

A company can experience high demand with the potential for great profit, but if its products cannot be produced efficiently and on time, then those profits cannot be realized. A well-managed shop floor ensures streamlined and efficient production to optimize safety, quality and profits.

What is shop floor management software?

Automated shop floor management systems speed production tasks and offer deeper insights into production data. ERP shop floor management software applications enable:

- Quick visibility into all shop floor activities and status

- Integrated, simplified shop floor processes

- Streamlined job data and production planning

- Labor tracking

- Work order tracking

- Embedded traceability

What are the benefits of shop floor management software?

Shop floor management software offers real-time shop floor controls that boost productivity, replacing cumbersome, unconnected spreadsheets with centralized, dynamically populated data and application integrations.

Cloud-based ERP solutions provide real-time shop floor insights that enable faster identification of production issues and bottlenecks, facilitating prompt corrective actions. Insights into resource utilization, scheduling and inventory allow for efficient allocation and adjustments to maximize output.

How does QT9 ERP help with shop floor management?

QT9 ERP’s Shop Floor Management module provides the tools you need to manage your shop’s workflows, including materials, build, job costing, time tracking and inventory. Shop floor processes are centralized and integrated with the rest of your business. Barcoding capabilities can be used to track labor, assign and track material inventory, and print labels on demand.

QT9 ERP provides more than 17 manufacturing applications, standard, as well as easy access to data and analytics to help manufacturers make the best decisions for moving forward. With QT9 ERP you get:

- 17+ modules, including BOM

- Quick implementation

- Tailored customer support

- Customer, compliance, supplier and physical inventory web portals

- Lot and serial number inventory control

- Access to digital business intelligence and analytics

- Seamless integration with QT9 QMS quality and compliance software

What’s more, you’ll get unlimited training, unlimited customer support, free software updates and tailored implementation support, all at an affordable price point.

Reach out today to see what QT9 ERP can do for you.

Experience QT9 ERP in action today

Schedule your personalized demo and start a free trial.