Bill of materials (BOM) software for manufacturers

The QT9™ ERP Bill of Materials (BOM) solution makes it easy to create a comprehensive list of components, labor and equipment required to build a product.

Connect bill of materials to the rest of your business

Enable purchasing, manufacturing, scheduling and planning to work as one.

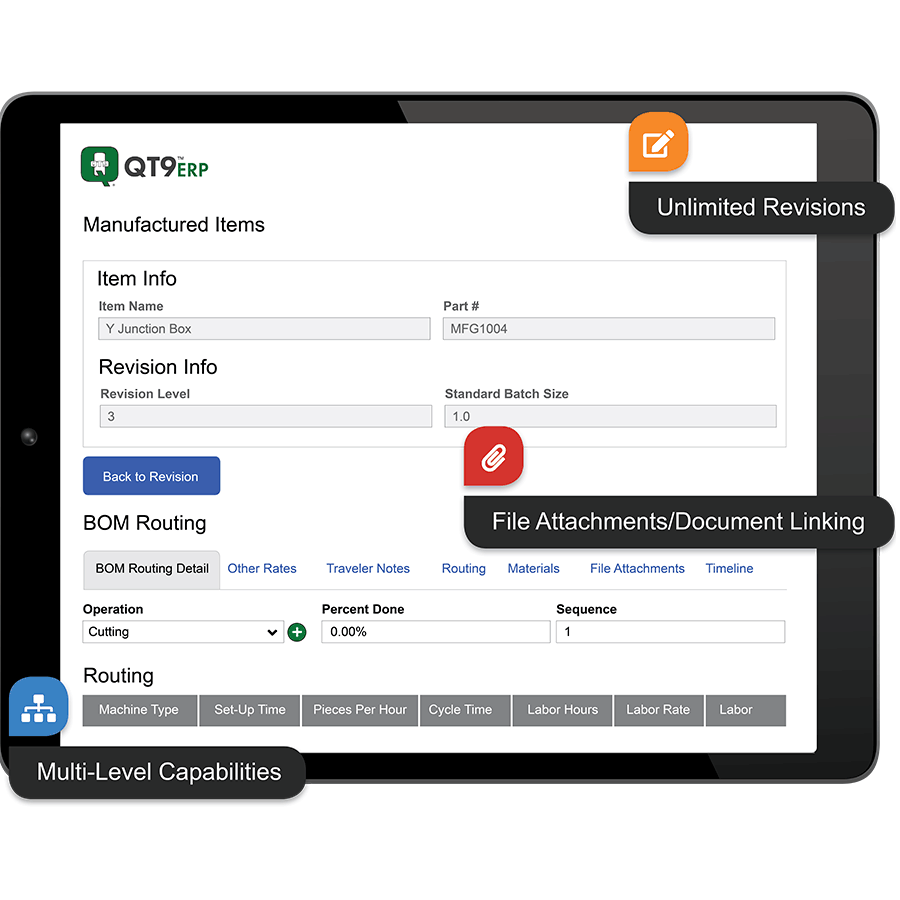

Unlimited revisions

Create unlimited revisions of products with full traceability to each revision in inventory, orders and manufacturing.

Multi-level capabilities

Explode your bill of materials multiple levels deep to give you visibility on material needs.

Increase planning capacity

Active bill of materials, combined with production needs, orders, purchasing and inventory, easily fuels MRP planning.

UNIFY BOM PRODUCT INFORMATION

Simplify bill of materials

-

Easily build a Bill of Materials (BOM) by importing from other BOMs or creating from scratch. Our Bill of Materials Software simplifies this process by providing a centralized, flexible solution for managing all your BOM details.

-

Track other rates such as overhead, indirect labor, machine rates, etc., per routing.

-

Add custom fields per routing that can be filled out with our shop floor manager.

-

Build out contract services and link to required suppliers per routing.

-

Centralize BOM records and eliminate the use of disconnected silos & manual collaboration.

-

Track cycle times/pieces per hour to help the job scheduler accurately schedule routings.

-

Build your unit cost based on materials, projected labor and other rates.

CONNECT PEOPLE, PRODUCTS & DATA

Modernize BOM processes

- Track revision history by what revision of your parts you have sold, manufactured and have in inventory.

- Quickly access a BOM record from virtually everywhere in the system and make revisions as often as needed wiith the supoprt of flexible Bill of Materials Software.

- Attach files to each revision of Bill of Materials. Whether they are drawings, contracts, approvals, etc., they will permanently stay with that BOM revision for complete visibility.

- Improve job routing accuracy by importing the correct information into the job routing for raw materials, cycle time/pieces per hour/set up time, estimated labor costs, etc.

- Maintain the right amount of inventory per location by automatically calculating stock levels, lead times and expiration dates.

- Enable links to QT9 QMS Inspections per routing of any Bill of Material.

Streamline workflow

-

Plan smarter by mapping out how long product manufacturing will take, what resources are needed and how many people need to be involved.

-

Receive automated alerts for minimum stock levels and soon-to-expire inventory.

-

Improve forecasting by building your manufacturing/purchasing plan around active BOM details.

-

Link a BOM straight to a quote and review margins, estimated labor and cost structures.

-

Be more adaptable by defining as many operations as needed, including contract services.

Easily Manage BOM Changes

Everything you need to get bill of materials done.

FAQs

What is a Bill of Materials (BOM)?

A Bill of Materials is a comprehensive list of all the raw materials, components, assemblies and subassemblies, along with instructions, that go into the manufacture, assembly or repair of a product.

Using a hierarchical structure, a BOM provides detailed information about every part and step required to create the final product, with the finished product at the top and the individual components and raw materials populating the bottom levels.

What is included in the BOM?

Key elements of a BOM include:

- Part identifiers, such as a name or number

- Descriptions – brief explanations of a part or assembly that reinforce identification, such as size

- Quantities

- Unit of measure

- BOM level – usually a unique number indicating where each part or assembly fits in relation to other assemblies and the final product

- Routing – indicates at which point in the manufacturing process the material is needed

- Procurement type - indicates whether a component is to be purchased, produced internally or manufactured by a third party

What are the types of Bill of Materials?

The most common types of BOMs include:

Engineering Bill of Materials (EBOM)

EBOMs are created during the product design phase and include detailed engineering specifications for parts, components and subassemblies, technical drawings and instructions developed by product engineers.

Manufacturing Bill of Materials (MBOM)

MBOMs focus on product production, identifying all of the parts and assemblies for a particular product and specifying how materials are to be assembled. These BOMs cover every aspect of production necessary to build and ship a product, including packaging.

An MBOM is also important in that it identifies what parts are needed at each stage of production, helping manufacturers better manage the purchase and delivery dates of raw materials, and ultimately the final product.

Service Bill of Materials

A service BOM is often created during a product’s engineering phase. It lists the replaceable parts and instructions for product maintenance. It is used for servicing and repairing products.

Single-Level BOM and Multilevel BOM

BOMs can be structured as single-level or multilevel, depending on the complexity of the product and the manufacturing process.

A single-level BOM provides a straightforward list of components needed to create a product. It does not account for subassemblies or hierarchical relationships between components. It is best for simple products with few components.

A multilevel BOM includes all components and their hierarchical relationships, detailing subassemblies and how they contribute to the final product. Each subassembly has its own BOM nested within the main BOM. Multilevel BOMs are used for complex products with multiple assemblies, such as a vehicle.

What does Bill of Materials software do?

Bill of Materials software automates the creation and use of BOMs, decreasing errors and making it easier to initiate changes and reworks. BOM software avoids manual processes associated with spreadsheets, helping to prevent inconsistencies, duplications and omissions that may result in production delays and wasted resources.

What are the benefits of using BOM software?

Bill of Materials software not only creates major efficiencies in design and production processes, it also enables greater accuracy and control. With it, manufacturers can automate data entry and document updates, which can then automatically populate across the system.

BOM software centralizes all BOM information, promoting better collaboration and ensuring team members are working with the latest and most accurate information. Businesses get automatic full traceability for easier regulatory compliance. As operations grow, BOM software can handle increasing complexity, including multilevel BOMs able to identify and track thousands of components.

Experience QT9 ERP in action today

Schedule your personalized demo and start a free trial.