Precision stocking with inventory management software

QT9™ ERP makes it easy to keep enough inventory on hand in the right locations to meet demand.

Connect inventory levels to different parts of your business

Transactional inventory

Track each inventory transaction back to the business function that created it for a complete audit trail.

Physical inventory

Track unlimited physical counts and compare the counts to your existing perpetual inventory.

Work in process

Track work in process, manufactured items and purchased items with email alerts and work-in-process dashboard.

Auto-inventory allocation

Automatically allocate lot-specific inventory to open jobs based on LIFO or FIFO.

Simplify inventory control

QT9's inventory management software takes the complexity out of ordering the right amount of inventory with built-in notifications that reduce surprises.

-

Capture real-time inventory levels in our intuitive inventory dashboards, so you know how much inventory you have on hand.

-

Streamline inventory management by synchronizing available inventory, inventory in transit, reorder quantities and inventory costs.

-

Set up automatic reorder points based on sales volume and supplier lead times. Set your jobs to auto-allocate inventory. Synchronize stock with sales orders.

-

Enable multi-location inventory tracking to track inventory across locations anywhere.

-

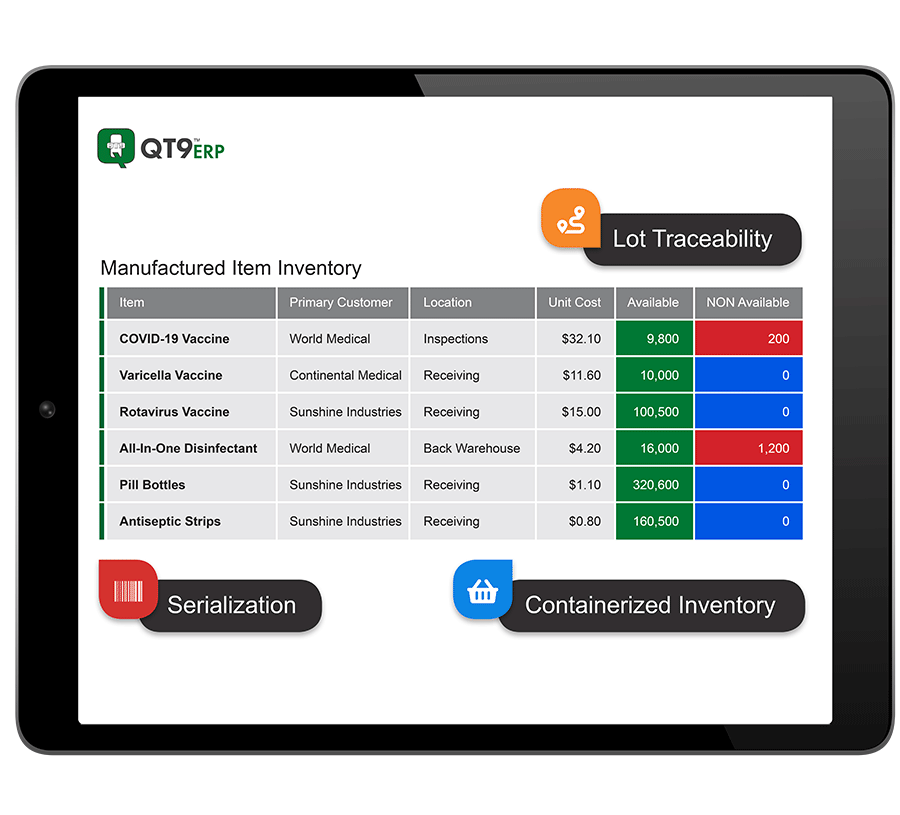

Track by lot number or serial number including accurate unit cost per lot whether it is purchased item inventory from purchasing or manufactured item inventory from our jobs module.

-

Disposition quarantined inventory by making simple adjustments.

Modernize inventory processes

Transform your manufacturing and supply chain operations by integrating sales forecasts with purchasing, production, inventory, shipping and warehouse management for greater efficiency with inventory management software.

-

Reveal predictive insights by compiling all your data into a single solution. Forecast to improve production schedules and meet customer demands.

-

Receive automated alerts for minimum stock levels and soon-to-expire inventory.

-

Barcode inventory to utilize scanning in Shop Floor Manager.

-

Use physical inventory app to track cycle counts and full physical inventories with barcoding.

-

Integrate inventory levels into MRP planning calculations.

-

Put inventory control on autopilot by auto-allocating inventory and automating inventory level notifications to prevent shortages.

Maximize resources

Plan smarter by automatically calculating stock levels and lead times. Stop wasting time searching for lost inventory and warehouse space.

-

Prevent shortages so you don't run out of stock.

-

Scale inventory levels to best optimize your warehouse space and consumption rate.

-

Maintain less stock by gaining control of your data and setting reorder points to optimize supply chain management.

-

Reduce costs by only producing what you need, when you need it. Plan material purchases based on demand - keeping your inventory just-in-time.

Streamline workflows

Monitor inventory from anywhere with help of inventory management software, so you can spend more time making a positive difference for your organization in other meaningful ways.

-

Increase inventory accuracy and improve production planning by automatically calculating stock levels and lead times

-

Experience total traceability by tracking every move from purchase to manufacturing to the warehouse to the sales order by lot number or serial number.

-

Capture inventory transactions to ensure every inventory transaction can be traced back to the business function that created it. See what materials went into any job, when you bought them, and who you bought them from.

-

Manage expiration dates to help ensure the quality of your inventory.

Centralize all your operations in one place

Connect data across business operations to reduce data silos. QT9 ERP integrates data to help you see everything in one place.

FAQs

What is inventory control?

Inventory control is the process of managing a company’s inventory from the time it is received to the time it is disposed of, whether on the shelf, in transit or in production. The goal of inventory control is to ensure there is always enough stock on hand to meet demand without carrying too much stock that the cost of keeping it eats into profit.

What is inventory control software?

Inventory control software centralizes and streamlines inventory control processes, tracking and managing inventory so a business can quickly know what stock it has. The software gives users detailed information about inventory on hand, including what, how many and where located. That data is integrated with sales, purchasing and accounting processes to streamline order fulfillment and fuel related business activities.

What is the benefit of using inventory control software?

Inventory control software simplifies and centralizes basic inventory management processes and provides visibility into stock levels, helping companies avoid overstocking and stockouts.

More advanced inventory management software offers real-time insights into a business’ inventory, allowing it to be more agile and make more impactful decisions.

Major benefits include:

- Cost savings

- Increased productivity

- Production optimization

- More accurate financial reporting

- Greater customer satisfaction

How can QT9 ERP help me with inventory control?

QT9 ERP automates all of your inventory management processes, gives you real-time insight into stock levels and locations, and provides advanced features that help you integrate inventory control into the success of broader operations.

With QT9 ERP you get:

- Real-time, centralized inventory control

- Barcoding and scanning

- Warehouse management

- Bill of Materials (BOM) tracking

- Lot and Serial Traceability

- Manufacturing operations integration

- Job scheduling

- Supply chain management

QT9 ERP seamlessly integrates with QT9’s highly rated quality management system (QMS) software. What’s more, you’ll get unlimited training, unlimited customer support, free software updates and tailored implementation support.

Experience QT9 ERP in action today

Schedule your personalized demo and start a free trial.